How Double Edge Safety Razor Blades Are Made

Introduction: From Bronze Tools to Precision Stainless Steel

From sharpened stones and bronze tools to precision-engineered Swedish stainless steel, shaving has evolved dramatically. The modern double-edged safety razor blade, a traditional grooming staple that, when halved, is an ideal fit for straight razors, dates back to the early 1900s, when King C. Gillette invented the first disposable blade. What once required a trip to the barbershop has become a daily ritual for millions.

People around the world now highly value double-edge razor blades for their precision, durability, and superior shave quality, especially when crafted by skilled hands. But what makes these tiny slivers of steel so sharp, smooth, and dependable?

In this article, we'll take you through the entire production process, from raw stainless steel to the final polished edge, revealing the craftsmanship and technology that transforms simple steel into the perfect shave.

Production Process

The Foundation: Choosing the Right Steel for Razor Blades

Every high-quality shaving razor blade starts with the right material. Stainless steel, known for its corrosion resistance, strength, and long-lasting durability, has become the industry standard for producing sharp, dependable safety razor blades. It is naturally hard and resistant, so it retains its integrity over time and avoids the rusting problems that other metals suffer from.

Steel is typically delivered to the production site in the form of coils, which are unrolled and processed into individual blades, most of which are double-edged and have two finely honed edges that provide a close, smooth shave.

Various grades of stainless steel are used in blade manufacturing. One of the most well-known is martensitic stainless steel, which is often sourced from Sweden. This is why many blades are advertised as being made of "premium Swedish steel." Martensitic stainless steel is valued for its hardness, wear resistance, and ability to maintain an extremely sharp edge. Carbon steel or specially treated alloys, sometimes enhanced with carbide additives, are also used to increase flexibility or refine grain structure. These material choices help slow blade deterioration and extend performance over time.

Choosing the right steel at the start of production is critical. It directly determines how sharp, durable, and comfortable the final razor blade will be, making the difference between an average shave and a truly exceptional one.

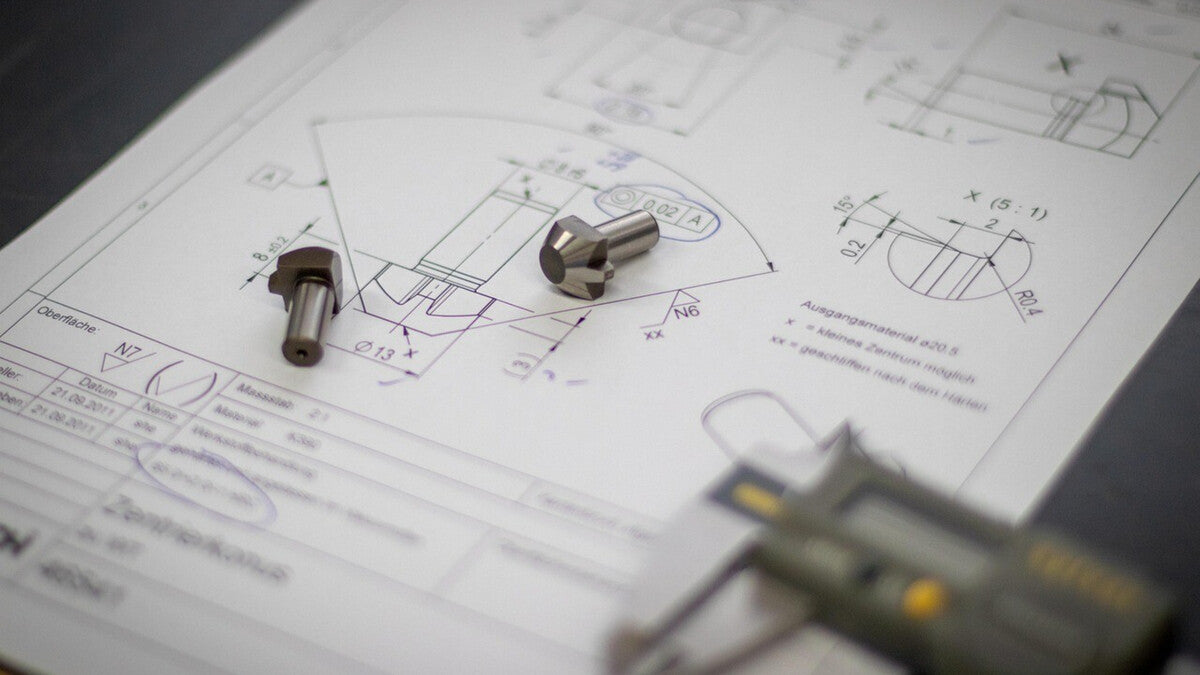

Blanking (Stamping the Blade Shape)

Blanking, which involves feeding stainless steel coils or sheets into a high-precision stamping machine, is the first step in the manufacturing process of double-edge and disposable blades. This step precisely cuts out the shape of each blade, resulting in uniform blanks ready for further processing.

Every cut must be precise to ensure the blade's future sharpness, fit, and safety. Blanking ensures that both traditional double-edge and cartridge razor blades have identical dimensions.

Hardening (Heat Treatment to Temper the Blade)

The stamped blanks are then heat treated in a vacuum chamber or furnace to increase the metal's hardness using a rapid cooling process known as quenching. This is critical for blades to become sharp and retain edge integrity after repeated use.

Tempering changes the steel from malleable to extremely rigid and resistant, making it ideal for enduring hone cycles and preventing dull edges. To avoid structural weaknesses or oxidation in martensitic or high-carbon blades, temperature and time must be carefully controlled.

Grinding and Polishing (Sharpening the Blade Edge)

Once hardened, the blades are fed through precision grinding machines, where submicron abrasives shape the cutting edge, remove burrs, and set the bevel. This process results in the razor's two sharp edges, which are then polished.

Polishing eliminates micro-imperfections and improves glide, thereby reducing skin irritation during shaving. Premium blades earn their reputation for exceptional sharpness and comfort here, which is what distinguishes high-quality manufacturers from the competition.

Coating (Protective and Glide Enhancements)

To enhance performance, blades receive a protective coating that improves glide and guards against corrosion. Common finishes include chromium plating and non-stick coatings such as PTFE (Teflon), both of which reduce friction and resist oxidation.

For certain variants, additional coatings like nickel or oil are applied, particularly to protect carbon steel blades. These finishes are essential for durability, smoothness, and longevity, ensuring blades deliver consistent shaves over multiple uses.

Assembly and Packaging

Blades are treated with a protective coating to improve glide and prevent corrosion. Common finishes include chromium plating and non-stick coatings like PTFE (Teflon), which reduce friction and resist oxidation.

Certain variants receive additional coatings such as nickel or oil, particularly to protect carbon steel blades. These finishes are critical for blade durability, smoothness, and longevity, ensuring consistent shaves across multiple uses.

Quality Control: Ensuring Every Blade Meets the Highest Standards

Before reaching the customer, each blade is subjected to rigorous quality control. Both visual and microscopic inspections detect flaws like dull edges, burrs, and misalignments. Sharpness is precisely measured, and additional tests ensure corrosion resistance, oxidation protection, and consistent performance across skin types.

Only blades that meet all specifications, from edge retention to structural integrity, are approved for packaging and sale. This ensures that every product that leaves the factory provides the same professional-quality shave.

Conclusion

From raw stainless steel to the final polished edge, the production of double-edge safety razor blades is a meticulous process that combines advanced technology and traditional craftsmanship.

Materials selection, precise stamping, controlled heat treatment, and expert grinding and polishing all contribute to sharp, long-lasting, and comfortable blades. Modern coatings such as chromium and PTFE (non-stick layers) increase blade life and improve glide, thereby protecting the skin from irritation.

Next time you shave, remember the precision and expertise that went into your blade, which is designed to deliver a smooth, close, and consistent shave every time.

FAQ: How Are Double Edge Razor Blades Made?

-

How are double-edge razor blades made?

Double-edge razor blades start as stainless steel coils, which are unrolled and cut into individual blades through a precise stamping or blanking process. The blades then undergo heat treatment, grinding, polishing, and coating before assembly. This process ensures the blades are sharp, durable, and ready for a smooth shave.

-

What materials are shaving razor blades made from?

Most blades are crafted from martensitic stainless steel for its hardness and corrosion resistance. Some blades are made of carbon steel, which requires protective coatings like chromium coating or oil to prevent rust.

-

Why is heat treatment important in blade manufacturing?

Heat treatment, including hardening and tempering, transforms the steel from malleable to hard and resistant, ensuring the blade is sharp enough and durable. This step helps blades maintain edge integrity and prevents dull edges.

-

What is the role of grinding and polishing in the blade production process?

Blades are sharpened using submicron precision abrasives in grinding machines, which form the cutting edges and remove burrs. Polishing further smooths the blade surface to reduce friction and prevent skin irritation during shaving.

-

What coatings are applied to razor blades and why?

A non-stick coating such as Teflon (PTFE) and chromium coating are applied to reduce friction, improve glide, and protect the blade from oxidation and wear. Carbon steel blades often get nickel plating or oil layers to prevent corrosion.

-

What is blade stropping, and does it affect blade sharpness?

Stropping is a technique used to maintain or restore sharpness by polishing the blade edge. While blades are precision sharpened during production, stropping can extend blade life between replacements.

-

How do manufacturers ensure the quality of each razor blade?

Each blade undergoes strict quality control with microscopic inspections to check for burrs, edge sharpness, alignment, and corrosion resistance. Only blades that meet all standards move to packaging.

-

Are double edge razor blades different from cartridge blades?

Yes, double-edge razor blades are thin, flat, and have two cutting edges, designed for safety razors. Cartridge blades are part of multi-blade heads and have different manufacturing processes and coatings.

-

How long do double-edge blades typically last?

Blade longevity depends on factors like material quality, coatings, and shaving habits, but precision manufacturing aims to maximize sharpness retention across multiple shaves.